Client

Completion Date

Designer

Location

Delivery Method

Division

Contract Value

The Dulles International Airport (IAD) East/West Automated People Mover (APM) transports airline passengers. The project includes a tier-one station, a tier-three station shell, an inner spur track, and a tunnel portal at the Vehicle Maintenance, the systems fit-out of the tunnel stations, and an emergency radio supplemental radiating system.

As part of the joint venture, Atkinson performed excavation and support work, encompassing more than 6,775 linear feet of rock excavation and averaging a depth of 50 feet. The team performed the support of excavation and cast-in-place concrete for the cut-and-cover tunnels and stations.

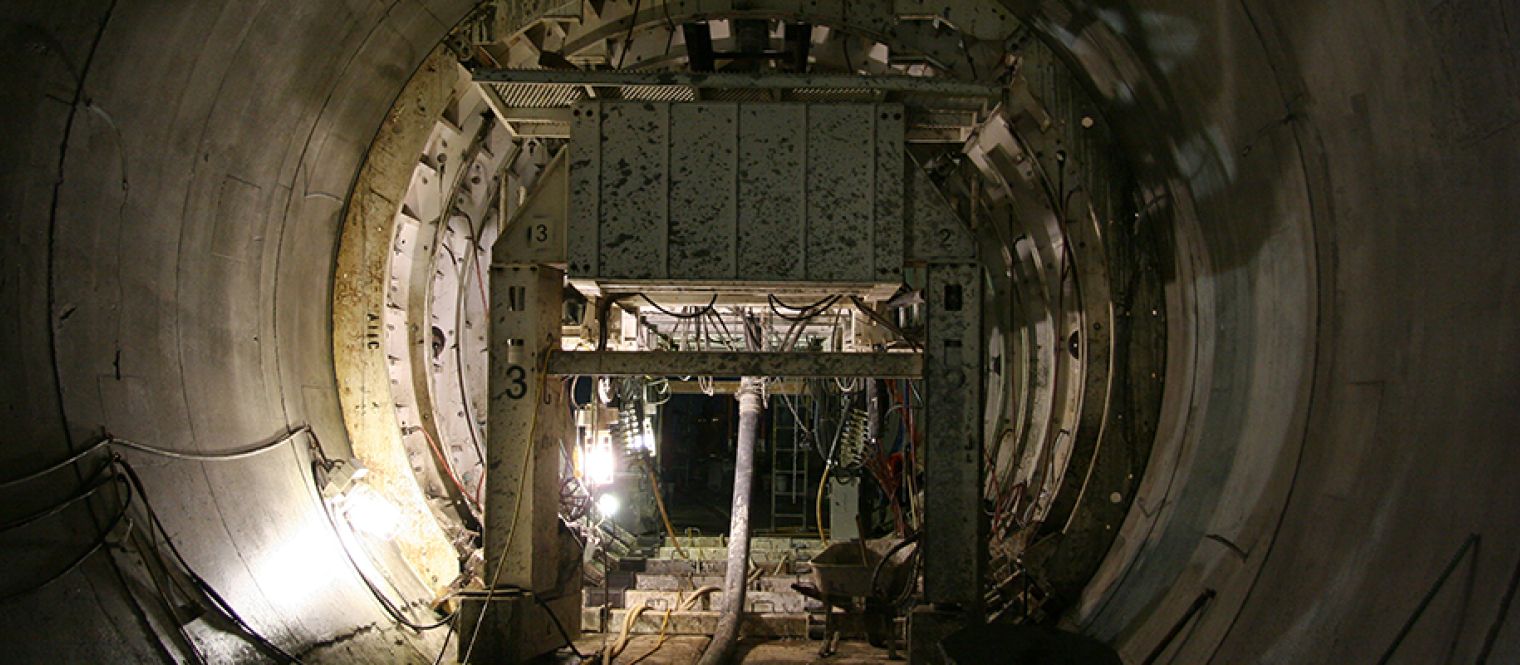

Two 21-foot diameter Robbins Single Shield Tunnel Boring Machines (TBM) were used to excavate over 3,600 linear feet of the tunnels. The machines were fitted with 15-inch disc cutters for excavation through relatively soft rock (UCS < 7,000 psi). Precast concrete segments were erected, concurrent with the excavation, within the tail shield to form the final tunnel lining. Both TBMs were moved through a 600-foot-long station, as well as negotiated radii as shallow as 410 feet to successfully complete each run.

On the northern end of the East APM, the team excavated two 400-foot-long, 22-foot diameter tunnels using NATM techniques. This system used roadheaders for excavation, robotic shotcrete application machines, and a very complex system of convergence and settlement monitors to determine the state of relaxation of the ground around the tunnel. NATM tunnels were excavated in one-meter advances of the 14-foot-high topheading, followed by immediate and occasionally concurrent application of up to 12-inch thick shotcrete. In the event surface subsidence was detected, additional shotcrete was applied, and the tunnel bench was removed to complete the excavation and form a complete circular structure—thereby limiting the potential for surface subsidence.

On the West APM, two 1,200-foot-long tunnels and two 210-foot-long tail tunnels were also excavated using NATM techniques. Surface subsidence was of great concern to the team throughout the project given all of the tunnels were excavated at shallow depths (less than two tunnel diameters) below active taxiways with settlement criteria of .25-inch at the taxiway surface. Throughout the excavation sequence, the shotcrete delivery system was kept continually active, enabling shotcrete application at any time during the excavation cycle.